VOLCANO® LB 100UV SLA and LB 380UV SLA Laser Optics

Systems > Solid State Laser Annealing

The VOLCANO LB 100UV SLA is designed for a line length of 100mm. The LB 100UV-1-8340 provides up to 500mJ/cm2 in a 100mm long line with a 50µm FLATTOP short axis operated with the TM 8340 (40mJ, 10 kHz, 400W).

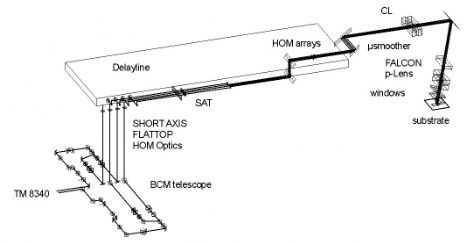

The LB 100UV systems are based on a rigid aluminum housing structure and the FALCON XL projection lens gives a working distance of >200mm. Line Beam Optics include a MBC (Manual Beam Control) camera system which allows to control and adjust position and angle of all laser emitted beams. The FALCON XL design contains one or two windows which seal the optics from the process chamber and protect against contaminations from the process.

The VOLCANO LB 100UV-SLA Laser Optics is optimized for UV Solid State Laser Annealing (SLA).

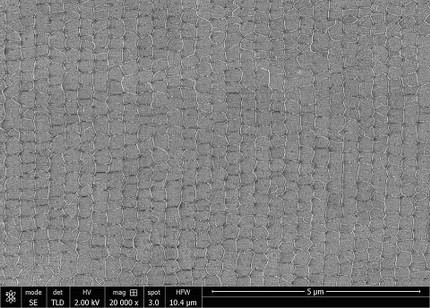

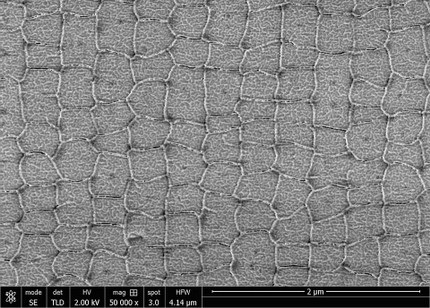

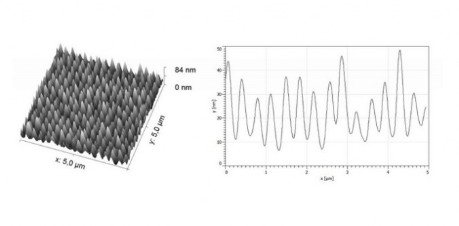

INNOVAVENT demonstrated in the application lab, that regular grain structures are obtained in a 45-55nm a-Si film with the 343nm pulsed Line Beam. The regular grain structure is mandatory in the manufacturing of Thin Film Transistors (TFT) for high resolution AMOLED displays.

VOLCANO LB 100UV-1-8340 set up

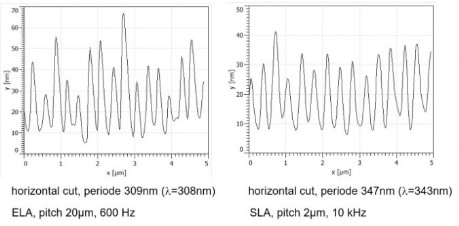

SLA SEMs of a VOLCANO 100UV SLA processed a-Si film showing a regular grain structure with a period about equal to the wavelength 343nm of the laser light (left overview, right detail).

AFM comparison for ELA and SLA Si films after annealing.

AFM comparison for ELA and SLA Si films after annealing.

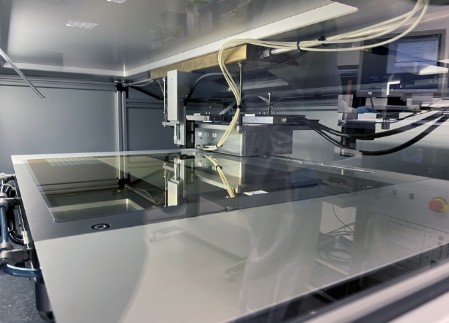

The VOLCANO LB 100UV SLA set up in the INNOVAVENT application lab includes a nitrogen purged process chamber to reduce the oxygen concentration at the sample to < 20ppm. The xy stage and vacuum chuck is prepThe VOLCANO LB 100UV SLA set up in the INNOVAVENT application lab includes a nitrogen purged process chamber to reduce the oxygen concentration at the sample to < 20ppm. The xy stage and vacuum chuck is prepared to process Gen 2 (370mm x 460mm) a-Si coated glass substrates.

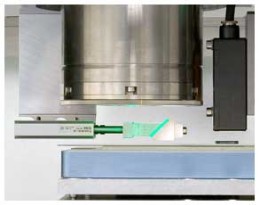

Process chamber and air bearing xy-stage

View into the Line Beam housing

TM 8340, 400W UV solid state laser

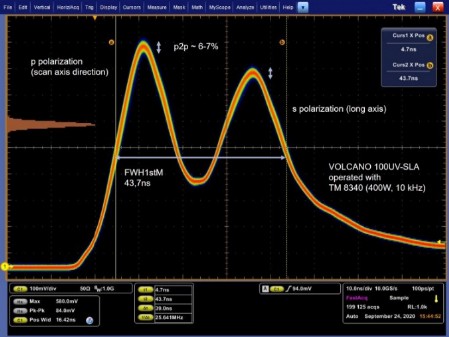

The key process parameters to make SLA available are the optimized pulse duration, controlling the temporal polarization and providing a uniform FLATTOP beam profile. The FLATTOP axis of 40-50µm matches with a pitch of 2-3µm resulting in 20-30mm/s scan speed and offering enhanced throughput compared to the slow 12mm/s (pitch 20µm) ELA scan speed at 600Hz. The UV laser light (343nm) emitting solid state laser TM 8340 reduces the operating costs and increases the uptime of production tools remarkably, compared to ELA systems using excimer lasers.

Temporal pulse shape variation over 195.125 pulses

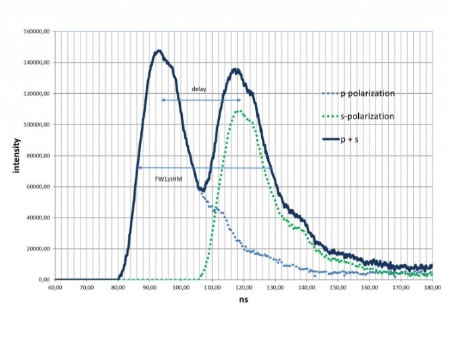

Temporal polarization control and pulse delay

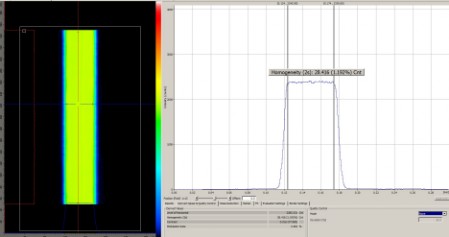

SAFT FLATTOP profile: 50µm width, <10µm steepness

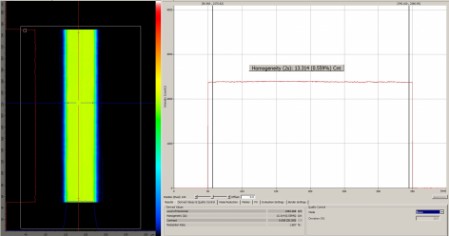

Profile long axis: 300mm

The VOLCANO LB 100UV SLA includes the following module options:

• Short Axis Flat Top (SAFT) optics

• Gaussian Short Axis (GSA) optics

• Polarization setting (in scan direction or in direction of the long axis or mixing long axis and scan direction)

• Pulse Delay and Temporal Profile control

• µ-smoothing module (dynamic shift of long axis while scanning)

• PISTAB (Peak Intensity Stabilization) module („real time“ compensation of slow laser power variation)

| Technical Data: VOLCANO® LB 100UV-2-8340 SLA | ||

| Wavelenght: | 343 nm | |

| Line length: | 100mm (top-hat-profile) | |

| Line width: | 40-50µm FLATTOP | |

| Homogeneity: | 2 Sigma ≤ 1.0% long axis | |

| Energy density: | ≥ 500mJ/cm² | |

| Pulse duration: | 15-20ns single pulse, optical delay 25-26ns | |

| Repetition rate: | 10kHz | |

| Laser: | 2x TruMicro 8320 (Trumpf Lasertechnik, Germany) | |

| Diagnostics: | laser power meter, substrate power meter, substrate beam profiler, fast photodiode | |

| Other line sizes and other configurations on request. | ||

| Technical Data: VOLCANO® LB 380UV-2-8340 SLA | ||

| Wavelenght: | 343 nm | |

| Line length: | 380mm (top-hat-profile) | |

| Line width: | 40-50µm FLATTOP | |

| Homogeneity: | 2 Sigma ≤ 1.0% long axis | |

| Energy density: | ≥ 300mJ/cm² | |

| Pulse duration: | 15-20ns single pulse, optical delay 25-26ns | |

| Repetition rate: | 10kHz | |

| Laser: | 2x TruMicro 8340 (Trumpf Lasertechnik, Germany) | |

| Diagnostics: | laser power meter, substrate power meter, substrate beam profiler, fast photodiode | |

| Other line sizes and other configurations on request. | ||

VOLCANO® Laser Optics include an integrated attenuator module to adjust the energy density at the substrate level. Power meter heads and a CCD camera based beam profile measurement tool are available.